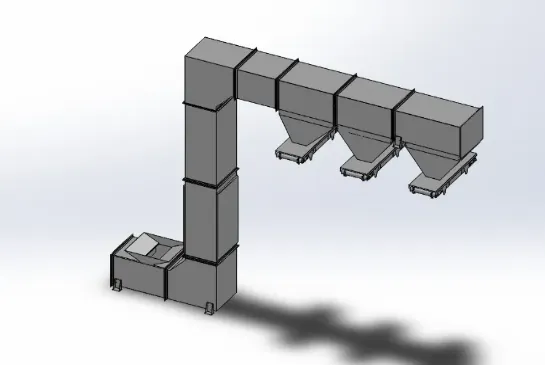

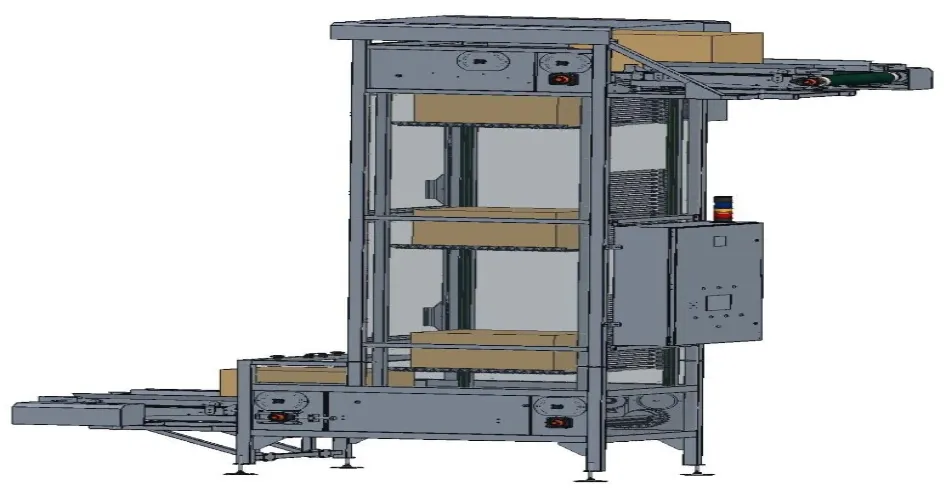

Feeding System

Best Innovations in Feeding Systems

Nexgen Engineering And Conveyors Pvt. Ltd. excels in delivering innovative feeding systems tailored to optimize efficiency and reliability. Our custom-built products are designed to meet the unique demands of diverse industrial applications with precision and quality.

By continuously integrating the latest technology and engineering expertise, Nexgen delivers exceptional products that drive success for businesses worldwide.

Tailored Feeding Systems for Diverse Industries

Nexgen specializes in designing tailored feeding systems to meet the unique needs of diverse industries. Our solutions are engineered for optimal performance, ensuring smooth and efficient material handling.

From automotive to food processing, we provide customizable systems that enhance productivity and reduce downtime. With our expertise, businesses can achieve streamlined operations and improved workflow.

Different Types of Feeding Systems

1. Bucket Elevator

2. Belt Elevator

3. Vertical Elevator

4. Turn Table

5. Telescopic Belt Conveyor

6. Dockless Truck Loading Conveyor

Our Products

Different Types Of Feeding Systems

FAQs